Automatic Quick Mold Change Cart | ISO 9001 Automatic Feeding Equipment Manufacturer | Shung Dar Industrial Co., LTD.

Based in Taiwan since 1982, Shung Dar Industrial Co., LTD. has been a Automatic Quick Mold Change Cart | steel coil stamping processing equipment manufacturer. CE, SGS & ISO 9001 certified, blanking Line system technical partnership with Japanese press manufacturer AIDA, and German press manufacturer Heilbronn, Shung Dar's machinery is sold in over 30 countries with solid reputation.

Based on industry 4.0, Shungdar‘s press equipment is designed with uncoiler, leveler, feeder, shear, transfer, stacking and automated stamping production processes. The coil processing, slitting and cut to length lines are designed with smart production line controls, as well as excellent service.

Shung Dar has been offering customers high-quality heavy duty single and double head uncoiler, rotary shear line, 3 in 1 NC servo feeder, straightener & uncoiler since 1982, both with advanced technology and 36 years of experience, Shung Dar ensures each customer's demands are met.

View our quality products

Uncoiler & Straightener,

NC Servo Feeder,

Metal Sheet Straightener,

Metal Coil Feeder,

Single Head Uncoiler,

Double Head Uncoiler,

Transformer Core Cutting Line,

Coil Processing Blanking Line,

Scroll Slitting Line,

Zig Zag Feeding Line,

Floor Stand Robot System,

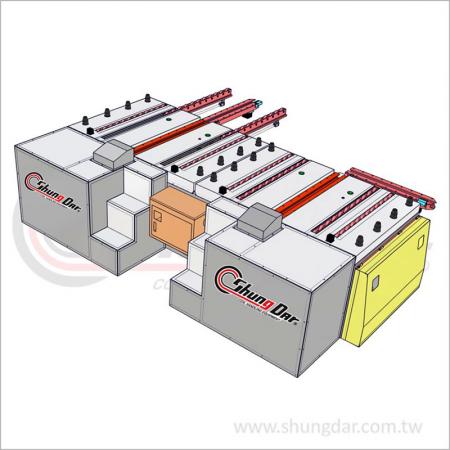

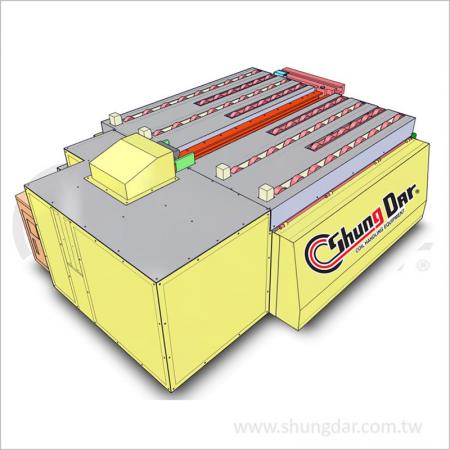

Automatic Quick Mold Change Cart,

Automatic Processing Transfer System and feel free to

Contact Us.