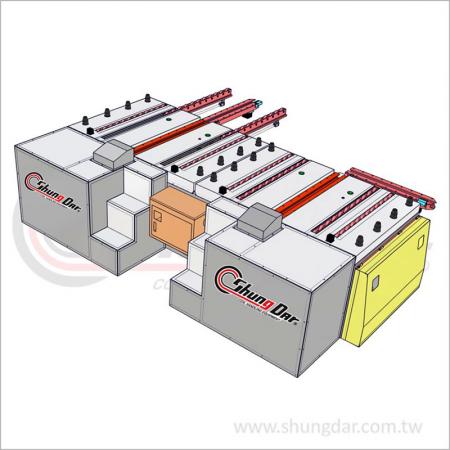

Automatic Quick Mold Change Cart - Double Stations Cart

CAR2

Mold Exchange Cart For Press, Die and Mold Change Cart, Double stations Die / Mold Cart System, Dual Stations Mold Change Handling Equipment

Quick Mold Change Cart is also called die cart, After the used mold is pulled out and placed in the mold to be used, the die cart returns to the original position. The double-stations cart can load two molds and exchange in the fastest time, saving the punching standby time and meeting the need to change the mold frequently during production.

Customized design for different punch specifications and operating systems. Application industries such as automobile sheet metal, automobile and motorcycle components, large household appliances, Electronic products (mobile phones, laptops) and other stamping forming production.

Die/mold change cart moves around the track to complete the changing operations, cart positioning, pusher pull mold out of press to the cart and pusher push mold into press. There must be enough space for the mold to move to the left or right sides of the punching machine. The mold loading direction can be main side or the lateral of the press. The system can be used for mold changing operations such as injection molding machines, punch presses and hydraulic presses.

The mold exchange cart can be planned to be fixed or telescopic according to the customer's local requirements; the advantage of the fixed relay station is that the traditional mechanical principle is adopted to effectively reduce the occurrence of the mold exchange cart; the telescopic relay station can greatly increase the punch space usage, and at the same time It also reduces the space occupied by the relay station.

Features

1. Suitable for production types with high mold exchange frequency.

2. Shorten the mold exchange time and increase the production efficiency.

3. Labor saving and time saving, fast and accurate changeover.

4. Lower budget and safety working enviorment.

5. Production line intelligent management.

Specification

| Specification | Mold / Die Exchange Cart | |

|---|---|---|

| Model | CAR2-1880-5T | CAR2-2210-10T |

| Size of Mold Template L x W (mm) | 1800 x 800 | 2200 x 1000 |

| Mold Weight x Qty (kgs x pcs) | 5,000 x 2 | 10,000 x 2 |

| Mold Pusher | AC Motor with Inverter / Manual | |

| Travelling Speed (m/min) | 5 | |

| Cart Position Type | Hydraulic / Fixed | |

** It can be customized according to customer's requirement.

- Photo Gallery

- Videos

-

Shung Dar Quick Mold Change Cart System for Press

- ecatalog Download

Automatic Quick Mold Change Cart - Double Stations Cart | Over 37 Years. Sold in 30 Countries World-Class Automation Steel Coil Stamping Equipment Manufacturer | Shung Dar Industrial Co., LTD.

Based in Taiwan since 1982, Shung Dar Industrial Co., LTD. has been a steel coil stamping processing equipment manufacturer. CE, SGS & ISO 9001 certified, blanking Line system technical partnership with Japanese press manufacturer AIDA, and German press manufacturer Heilbronn, Shung Dar's machinery is sold in over 30 countries with solid reputation.

Based on industry 4.0, Shungdar‘s press equipment is designed with uncoiler, leveler, feeder, shear, transfer, stacking and automated stamping production processes. The coil processing, slitting and cut to length lines are designed with smart production line controls, as well as excellent service.

Shung Dar has been offering customers high-quality heavy duty single and double head uncoiler, rotary shear line, 3 in 1 NC servo feeder, straightener & uncoiler since 1982, both with advanced technology and 36 years of experience, Shung Dar ensures each customer's demands are met.