Automatic Quick Mold Change Cart

Mold Exchange Cart for Press, Die and Mold Change Cart, Die / Mold Cart System, Mold Change Handling Equipment

Shung Dar - Automatic Quick Change Mold System, with the goal of production automation, improve the machine utilization, shorten the standby time of the press, and provide customized design for different punch specifications and operating systems.

Application industry is suitable for automobile sheet metal, automobile and motorcycle components, large household appliances (air-conditioning, refrigerator, washing machine) and other stamping and forming production lines.

From removing the used mold, handling to another mold into the press, the mold replacement procedure is complete in the shortest time and the safety and accuracy of the mold changing operation. The introduction of an automatic mold change system is one of the necessary plans for the smooth upgrading of the stamping processing industry to a smart manufacturing plant. Regardless of the scale of the plant, the customer and Shungdar with fully communicates the future production capacity and equipment planning and it can combined with the steel coil feeding and stamping production line with stamping automation function to a complete intelligent production line. According to the different production needs of customers, we recommend the best production line configuration for you.

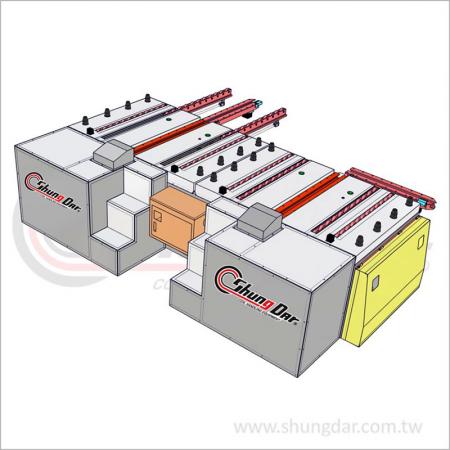

Automatic Quick Mold Change Cart - Double Stations Cart

CAR2

Quick Mold Change Cart is also called die cart, After the used mold is pulled out and placed...

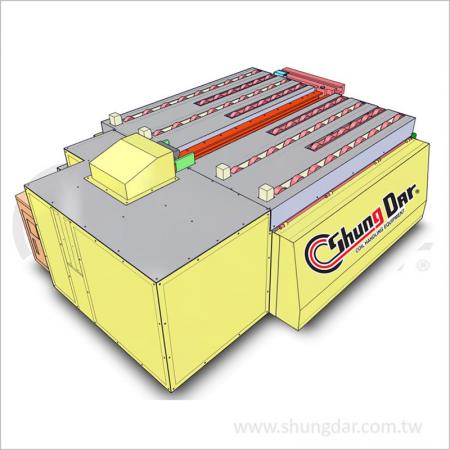

DetailsAutomatic Quick Mold Change Cart - Single Station Cart

CAR1

Quick Mold Change Cart is also called die cart, After the used mold is pulled out and placed...

DetailsAutomatic Quick Mold Change Cart | Taiwan-Based Steel Coil Pressing & Stamping Machine Manufacturer | Shung Dar Industrial Co., LTD.

Based in Taiwan since 1982, Shung Dar Industrial Co., LTD. has been a steel coil stamping processing equipment manufacturer. CE, SGS & ISO 9001 certified, blanking Line system technical partnership with Japanese press manufacturer AIDA, and German press manufacturer Heilbronn, Shung Dar's machinery is sold in over 30 countries with solid reputation.

Based on industry 4.0, Shungdar‘s press equipment is designed with uncoiler, leveler, feeder, shear, transfer, stacking and automated stamping production processes. The coil processing, slitting and cut to length lines are designed with smart production line controls, as well as excellent service.

Shung Dar has been offering customers high-quality heavy duty single and double head uncoiler, rotary shear line, 3 in 1 NC servo feeder, straightener & uncoiler since 1982, both with advanced technology and 36 years of experience, Shung Dar ensures each customer's demands are met.