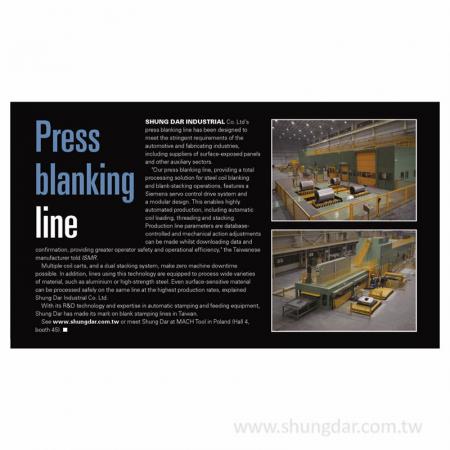

Press Blanking Line / Magnetic Stacking System

SL

Blanking Line of Sheet Metal, Steel Coil Blanking Line, Coil Processing Blanking Line

Magnetic stacking system to stack various automotive blanks precisely to the latest industry demands - includes Trapezoidal Sheet Stacking and Shaped Sheet Stacking, such as Engine Hood, Car trunk cover, Car body shell and Car cross rail.

The automatic blanking line is used to clean, and level the steel coils. It is equipped with a press and a die to stamp out the initial sheet metal shape, or to cut a rectangle, rectangle, triangle, trapezoid, etc. The shape of the sheet blank is transferred to the workstation at a high speed through the magnetic suction stacking system to be neatly stacked to facilitate the subsequent extrusion molding production line.

The operator selects or inputs corresponding information corresponding to the produced specifications into the control system, such as mold information, raw material information, etc., and the processing results automatically control each executing agency to complete the corresponding adjustment.

Features

Punch Blanking Line

1. High precision leveling mechanism.

2. Servo drive feeder, high feed accuracy.

3. Reducing material wasting.

4. Improve operator safety.

5. The maximum width can reach 2000mm, the thickness range is 0.3 ~ 6.0mm, and the maximum material weight is 35 tons. It can be customized according to the actual needs of customers.

Magnetic Stacking System

1. Significantly increase production efficiency, magnetic line speed: 120M / min,Faster than traditional stacking system.

2. Dual stacking system ensures that the entire line does not stop. Automatically exchange system, reducing the time for unloading after stacking.

3. Protect the surface of the material.

Specification

| Specification | SL Series | ||

|---|---|---|---|

| Coil Thickness (mm) | 0.3 ~ 3.2 | 0.6 ~ 4.5 | 0.8 ~ 6.0 |

| Coil Width (mm) | 1300 / 1600 / 2000 | ||

| Coil Weight (ton) | 15 / 20 / 25 / 30 | ||

- Photo Gallery

- Videos

-

Press Blanking Line

630tons ShungDar Auto Servo Blanking Line

800 tons automotive press blankig line

- ecatalog Download

Press Blanking Line / Magnetic Stacking System | Over 37 Years. Sold in 30 Countries World-Class Automation Steel Coil Stamping Equipment Manufacturer | Shung Dar Industrial Co., LTD.

Based in Taiwan since 1982, Shung Dar Industrial Co., LTD. has been a steel coil stamping processing equipment manufacturer. CE, SGS & ISO 9001 certified, blanking Line system technical partnership with Japanese press manufacturer AIDA, and German press manufacturer Heilbronn, Shung Dar's machinery is sold in over 30 countries with solid reputation.

Based on industry 4.0, Shungdar‘s press equipment is designed with uncoiler, leveler, feeder, shear, transfer, stacking and automated stamping production processes. The coil processing, slitting and cut to length lines are designed with smart production line controls, as well as excellent service.

Shung Dar has been offering customers high-quality heavy duty single and double head uncoiler, rotary shear line, 3 in 1 NC servo feeder, straightener & uncoiler since 1982, both with advanced technology and 36 years of experience, Shung Dar ensures each customer's demands are met.