Línea de corte por prensa / sistema de apilamiento magnético

SL

Línea de corte de chapa metálica, línea de corte de bobinas de acero, línea de corte de procesamiento de bobinas

Sistema de apilamiento magnético para apilar varios troqueles automotrices con precisión según las últimas demandas de la industria - incluye apilamiento de láminas trapezoidales y apilamiento de láminas conformadas, como capó de motor, tapa de maletero, carrocería de automóvil y travesaño de automóvil.

La línea de enmascaramiento automático se utiliza para limpiar y nivelar las bobinas de acero. Está equipada con una prensa y un troquel para estampar la forma inicial de la chapa de metal, o para cortar un rectángulo, rectángulo, triángulo, trapecio, etc. La forma de la chapa en blanco se transfiere a la estación de trabajo a alta velocidad a través del sistema de apilamiento de succión magnética para ser apilada ordenadamente y facilitar la línea de producción de moldeo por extrusión posterior.

El operador selecciona o ingresa la información correspondiente a las especificaciones producidas en el sistema de control, como información del molde, información de la materia prima, etc., y los resultados del procesamiento controlan automáticamente cada agencia ejecutora para completar el ajuste correspondiente.

Características

Línea de Corte por Punzonado

1. Mecanismo de nivelación de alta precisión.

2. Alimentador de accionamiento servo, alta precisión de alimentación.

3. Reducción del desperdicio de material.

4. Mejorar la seguridad del operador.

5. El ancho máximo puede alcanzar 2000 mm, el rango de espesor es de 0.3 ~ 6.0 mm y el peso máximo del material es de 35 toneladas. Se puede personalizar de acuerdo a las necesidades reales de los clientes.

Sistema de Apilado Magnético

1. Aumentar significativamente la eficiencia de producción, velocidad de línea magnética: 120 m/min, más rápido que el sistema de apilado tradicional.

2. El sistema de apilado dual asegura que toda la línea no se detenga. Sistema de intercambio automático, reduciendo el tiempo de descarga después del apilado.

3. Proteger la superficie del material.

Especificación

| Especificación | Serie SL | ||

|---|---|---|---|

| Espesor de la bobina (mm) | 0.3 ~ 3.2 | 0.6 ~ 4.5 | 0.8 ~ 6.0 |

| Ancho de la bobina (mm) | 1300 / 1600 / 2000 | ||

| Peso de la bobina (tonelada) | 15 / 20 / 25 / 30 | ||

- Galería de fotos

- Vídeos

-

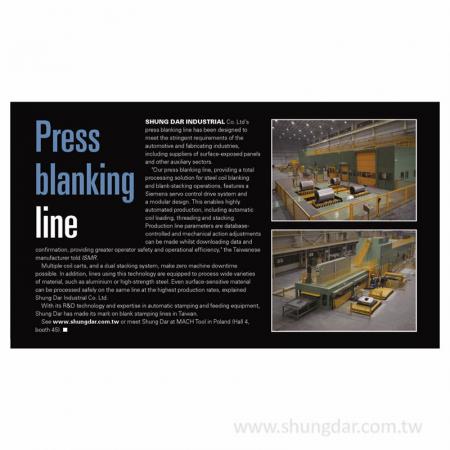

Línea de corte de prensa

Línea de corte automática ShungDar de 630 toneladas

Línea de corte de prensa automotriz de 800 toneladas

- Descarga de ecatalog

Línea de corte por prensa / sistema de apilamiento magnético | Más de 37 años. Vendidos en 30 países. Fabricante de equipos de estampado de bobinas de acero de automatización de clase mundial | Shung Dar Industrial Co., LTD.

Con sede en Taiwán desde 1982, Shung Dar Industrial Co., LTD. ha sido un fabricante de equipos de procesamiento de bobinas de acero. Certificado CE, SGS e ISO 9001, asociación técnica de sistemas de línea de corte con el fabricante japonés de prensas AIDA y el fabricante alemán de prensas Heilbronn, la maquinaria de Shung Dar se vende en más de 30 países con una sólida reputación.

Basado en la industria 4.0, el equipo de prensa de Shungdar está diseñado con desenrollador, nivelador, alimentador, cizalla, transferencia, apilamiento y procesos de producción de estampado automatizados. Las líneas de procesamiento de bobinas, corte y longitud están diseñadas con controles de línea de producción inteligentes, así como un excelente servicio.

Shung Dar ha estado ofreciendo a sus clientes desenrolladores de cabezal simple y doble de alta calidad, línea de corte rotativa, alimentador NC servo 3 en 1, enderezador y desenrollador desde 1982. Con tecnología avanzada y 36 años de experiencia, Shung Dar garantiza que se satisfagan las demandas de cada cliente.